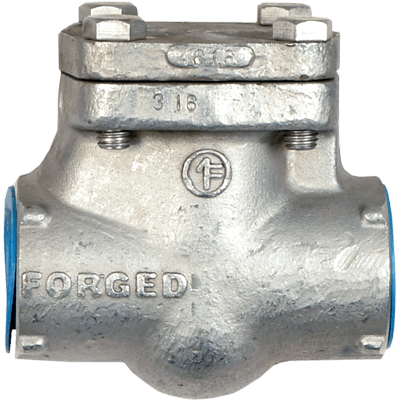

Forged Steel Check Valves

Seamless operation, accurate flow control

IPC’s forged steel check valves – setting new standards in performance and reliability. Designed for chemical, petrochemical, pharmaceutical, steel, food, power and water/steam industries. Experience seamless operation with optional electrical actuator automation. Choose from socket weld, butt weld or screwed end connections for easy integration. Trust in their durability, precision and adaptability to elevate your processes. Join satisfied customers who rely on IPC’s check valves for exceptional results.

Benefits

Smooth and fast operation

Sturdy design so as to withstand rough operational conditions of Check Valves

Manufacturing with advanced processes for best results and longevity

Excellent sealing efficiency

Specifications

General design & mfg API 602/ISO 15761/B 16.34

Pressure Temperature rating ASME B 16.34

Face to face dimensions Manufacturer's standard

Inspection and testing API 598 / BS 12266-1

End connections ASME B 16.11, ASME B 16.25

Size range DN 15 to DN 50

Seat leakage API 598

Pressure rating 800 / 1500 / 2500 / 4500

Features

Various trim materials are available (in accordance with API 602)

Gland packings can be replaced without removing the valve from the pipeline

Actuated valves can be provided with pneumatic / electrical actuator

In pressure classes #1500 and above, bonnets come in welded design

Lift check valve can be used in horizontal as well as vertical pipelines

Valves are available in socket weld, butt weld, screwed and welded

Certifications

Valves Approvals

Downloads

Frequently Asked Questions

The forging is like strengthening metal through intense pressure. This process creates a denser, more uniform grain structure compared to casting. The result is a valve body with exceptional strength, superior impact resistance, and better performance under high pressure and temperature. It’s the go-to choice for tougher, more critical services.

A check valve is a simple but crucial component, it’s a one-way street for flow. It automatically allows fluid to pass in one direction and closes to prevent any dangerous or inefficient backflow in the piping system when flow stops or reverses, protecting your equipment.

Our forged steel check valves are built for reliability across a wide range of demanding industries. They are commonly specified for chemical and petrochemical plants, pharmaceuticals, power generation (for water/steam lines), steel production, and food processing anywhere you need robust, leak-free backflow prevention.

To ensure easy integration into your existing piping, we offer multiple standard end connections. You can choose from socket weld, butt weld, or screwed (threaded) ends based on your system’s design and installation requirements.

Yes, absolutely! While they function automatically to prevent backflow, you can also opt for electrical actuator automation. This allows for remote operational control and integration into your larger process control system, adding a layer of management and monitoring.

As a leading manufacturer, we combine specialized material expertise with precision engineering. Our forged steel check valves are built for durability, precise operation, and seamless integration. You get a reliable product that delivers exceptional results and adapts to your specific process needs, backed by our technical support.