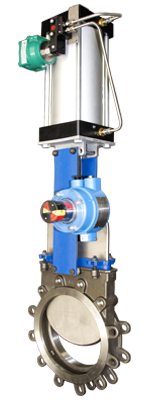

Knife Edge Gate Valve

Speciality Valve for abrasive applications

IPC Valves’ knife-edged gate valves are specifically engineered to excel in challenging environments, making them ideal for abrasive, viscous and powder applications. Their design enables efficient handling of slurries, pulp stocks and corrosive fluids in various process industries, requiring a resilient seat and precise shut-off. These valves find extensive use in waste-water treatment, pulp & paper, food, cement and powder industries, offering large sizes to ensure smooth operation even with thick flows.

Benefits

Designed for superior performance and long services life

Perfect valve for abrasive and slurry type applications

These valves can be supplied in both uni-directional and bidirectional configuration

Manual valves available with either hand wheel or gear

Automated valves can be supplied with various accessories

Specifications

General design & mfg MSS SP 81

Face-to-face dimensions Manufacturer's Standard

Inspection & testing MSS SP 81

Flange drilling ASME B 16.5

Size range DN40 to D600

Pressure rating PN10, PN16

Operating temperature range -29C to 200C

Features

Both soft seated and metal seated valves are available

Lug type cast stainless steel body

Available size range of DN 50 to DN 600 (consult factory for larger sizes)

Automated valves are available with either pneumatic or electric actuation like Limit switches, Air lock relays, Flow control valves, Volume boosters, Position transmitters etc.

Downloads

Frequently Asked Questions

They are the go-to choice for demanding applications involving slurries, powders, pulp stocks, wastewater sludge, and corrosive fluids. You’ll commonly find them providing reliable service in wastewater treatment plants, pulp & paper mills, food processing, cement production, and various powder handling industries.

IPC specializes in engineering valves for specific, challenging applications. Our knife edge valves are designed from the ground up to excel in abrasive and viscous environments, offering durability and precise control where it matters most for your process integrity.

Key factors include the specific type of abrasive or viscous media, particle size, flow rate, and pressure. Sharing these details with our technical team ensures we recommend the optimal materials and size from our range.