Let’s be honest: picking a valve is about more than pressure ratings and pipe size. The single biggest factor that determines whether your valve lasts for years or fails prematurely is the Material of Construction (MOC). Get it wrong, and you’re looking at leaks, unplanned shutdowns, and costly replacements.

Why Valve Material of Construction (MOC) Choice Isn't Obvious

It’s easy to default to a standard material like carbon steel to save on upfront costs. But if that carbon steel valve is exposed to wet carbon dioxide, it will corrode. Similarly, a standard 316 stainless steel valve might seem like a safe choice until it cracks in a chloride-rich environment.

The goal is to think beyond the initial purchase. You need a material that will survive not just the ideal conditions, but also the startups, shutdowns, and unexpected process hiccups.

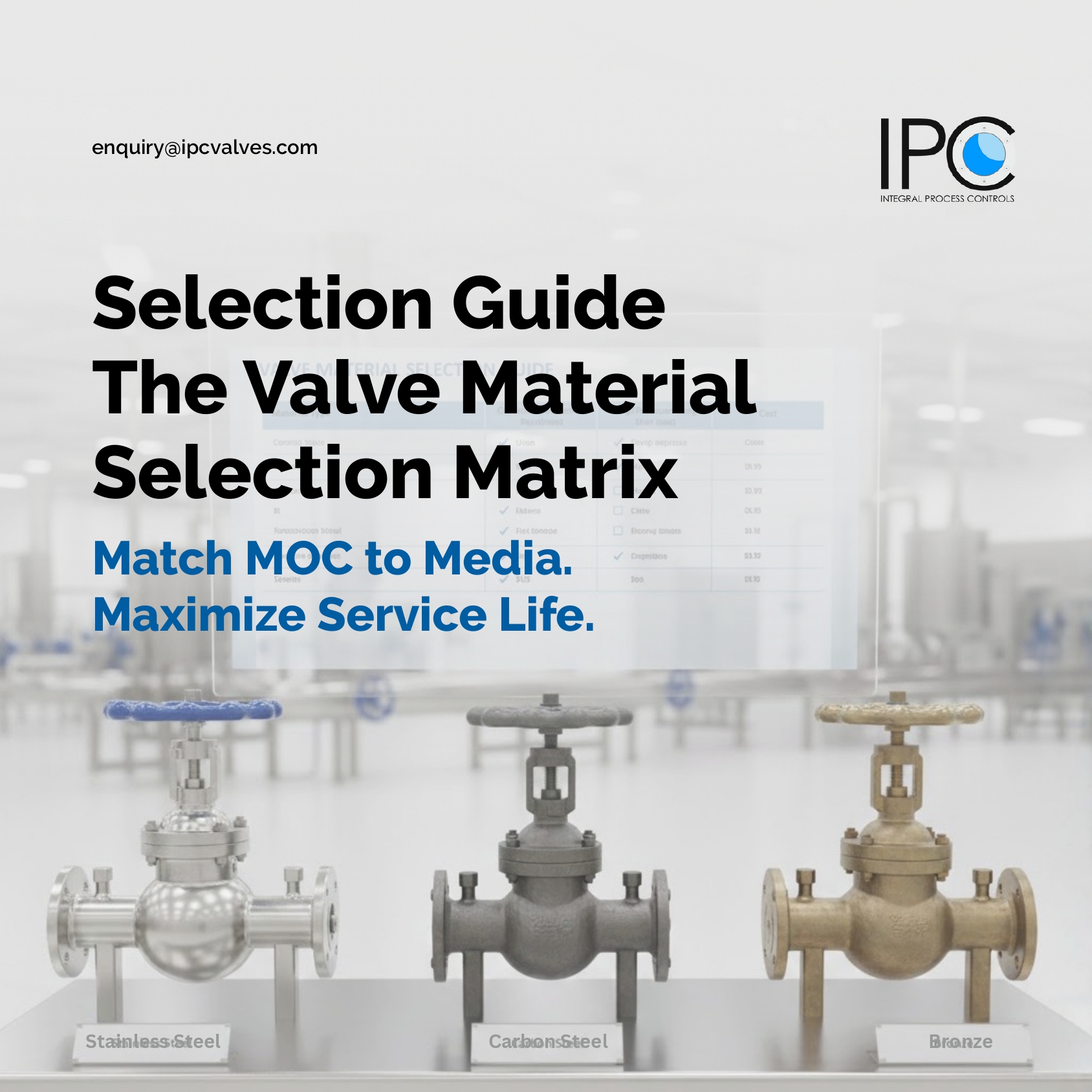

Your Practical Material Selection Matrix: Body and Trim Guidance

| Process Media / Service Condition | Recommended Body Material | Recommended Trim & Critical Notes |

| Dry Steam, General Water Services | Carbon Steel (A216 WCB) | 13Cr trim or stainless steel. A cost-effective and robust choice for non-corrosive services. |

| Wet Cold climate service lines, like fuel gas/ crude | Low temperature carbon steel A352 LCB/ LCC | SS 316 trim. Offers better low temperature. |

| Dilute Acids, Caustics, General Chemical Duty | Austenitic Stainless Steel (A351 CF8/CF8M - 304/316) | 316/316L trim. Excellent general corrosion resistance. Beware of chlorides. |

| Seawater, High Chloride, High Pressure/Temp | Duplex/Super Duplex Stainless ASTM A995/A890 Grade 4A/6A | Duplex trim. Superior strength and chloride stress corrosion cracking resistance. |

| Sour Service (H₂S Present) | NACE MR0175/ISO 15156 Compliant Materials | Hard-faced trim (e.g., Stellite). NACE compliance is mandatory to prevent sulfide stress cracking. |

| Severe Corrosion (Hot HCl, H₂SO₄) | High-Performance Alloys (Monel, Hastelloy) / PFA Lined trims | Matching alloy trim. For the most aggressive corrosion environments. |

| Abrasive Slurries, Catalytic Fines | Carbon Steel with Hardened Trim | Erosion-resistant trim (Stellite, hardened 17-4PH). |

Three Pro Tips Most People Miss

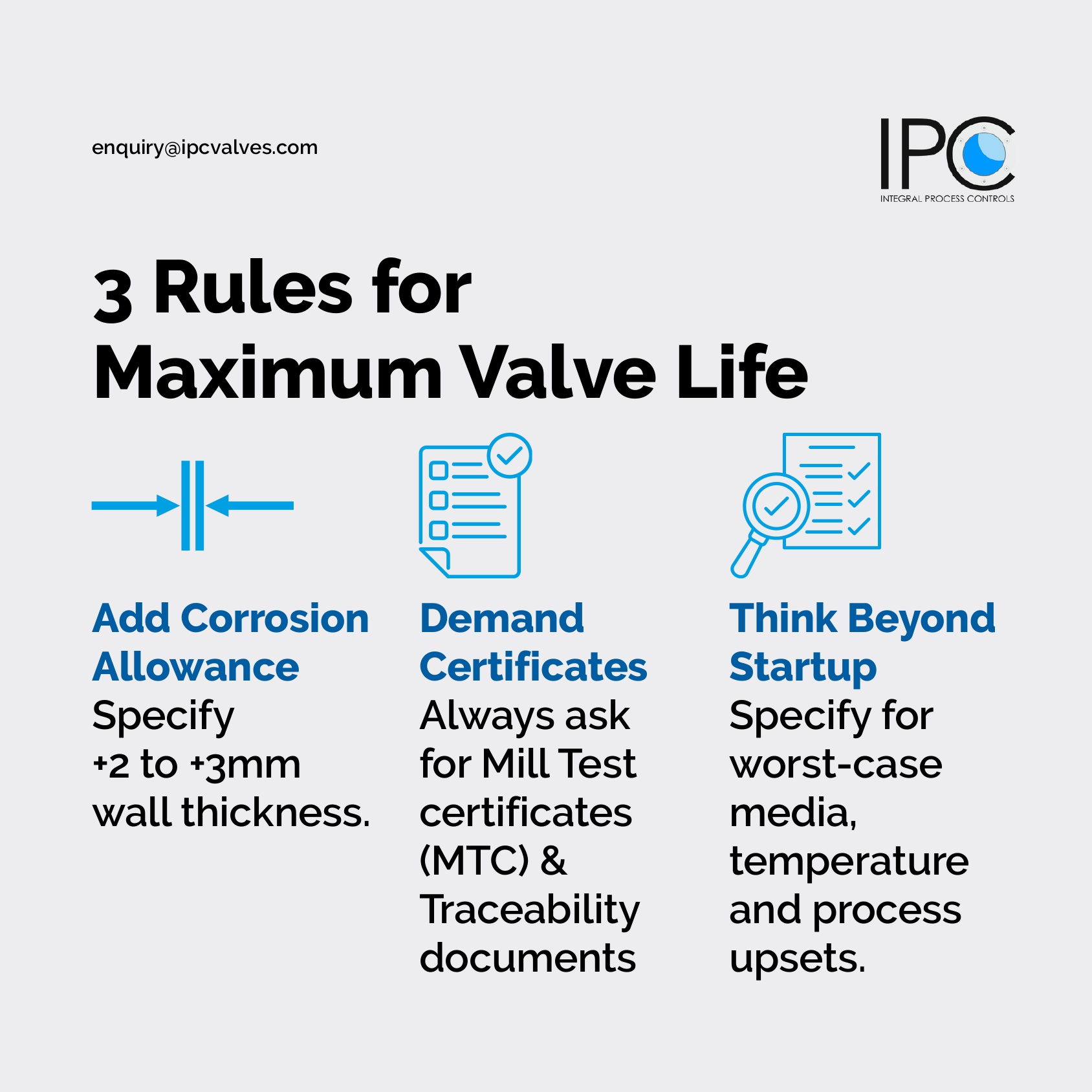

1. Plan for Wear and Tear: Always specify an extra 2-3mm corrosion allowance on the wall thickness if your process is known to be erosive or mildly corrosive. This simple step can double the valve’s service life.

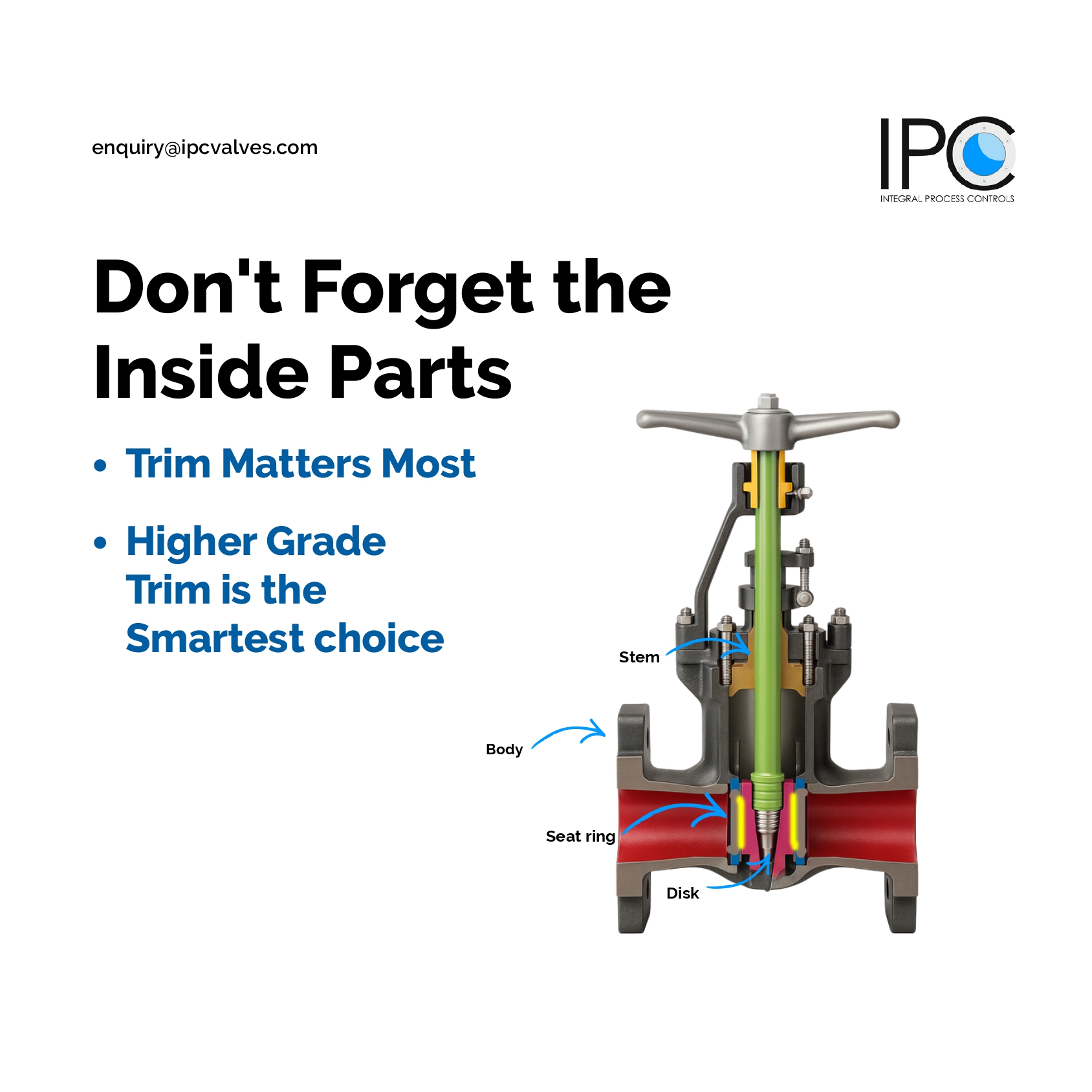

2. The Trim is Where the Action Is: In throttling applications, the trim takes the most punishment. Investing in a superior trim material (like hard-facing) often gives you a better return than upgrading the entire valve body.

3. Paperwork Matters: For critical services, don’t just take a supplier’s word for it. Ask for the Mill Test Certificates (MTCs) to prove the material grade. For sour service, you must see the NACE compliance documentation.

Let's Specify the Right Valve for Your Job

Our team of engineers isn’t here to just sell you a valve. We’re here to solve your flow control problem. With deep experience across power, oil & gas, chemicals, and steam, we help you make the material choice you won’t regret five years down the line.

The bottom line: Choosing the right valve material isn’t a guessing game. It’s a strategic decision based on your specific media and conditions. By following this practical framework, you can ensure your valves are a source of reliability, not a recurring headache.

Ready to specify with confidence? Our technical team is here to help. Contact IPC Valves for a material consultation tailored to your application.