Selecting the perfect valve for your application involves more than just choosing between a gate, globe, check or ball valve. One of the most critical, yet sometimes overlooked, decisions is the end connection. The choice between flanged, butt-weld and socket-weld connections directly impacts your system’s long-term integrity, installation cost, maintenance strategy and lifecycle performance.

For over 25 years, IPC has partnered with engineers across oil and gas, power generation, chemical and pharmaceutical sectors. This experience has shown us that the right end connection is not a mere accessory, it’s a foundational element of system reliability. Our experts’ cut through the complexity, providing a clear comparison to help you specify the optimal connection for pressure, temperature and operational needs.

Why Your Valve End Connection is a Strategic Decision

The end connection is the critical interface between your valve and the piping system. A mismatch can lead to leaks, reduced pressure rating, costly installation rework or difficulties during future maintenance. Your choice fundamentally influences:

- System Integrity & Leak Potential: The connection must maintain a perfect seal at the system’s operating pressure and temperature.

- Installation Time & Skill Required: Some connections require specialized welding and inspection, while others allow for quicker bolt-up.

- Lifecycle Maintenance & Replacement: Will the valve need to be removed for inspection or servicing? Some connections make this easy; others are not so easy.

- Total Cost of Ownership: Factor in not just the valve price, but also installation labor, required fittings and long-term maintenance access.

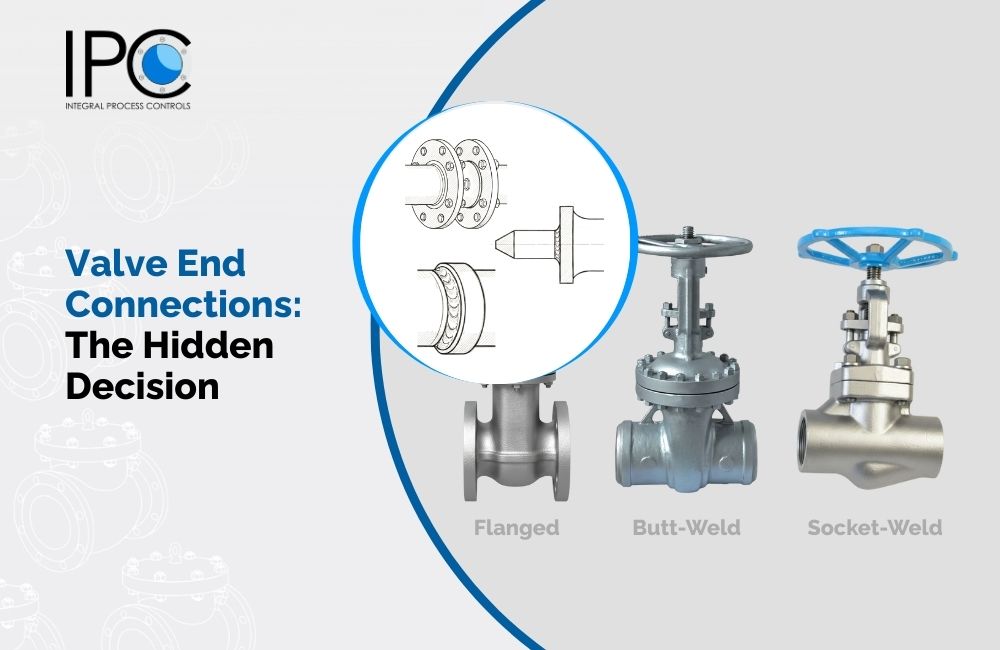

Valve End Connection Flanged, Butt-Weld & Socket-Weld: A Detailed Comparison

The following table provides a direct comparison of the three primary end connection types, highlighting their ideal use cases and key considerations.

Feature | Flanged Connections | Butt-Weld Connections | Socket-Weld Connections |

Primary Best Use | Systems requiring frequent maintenance, inspection or valve replacement. Low to medium pressure/temperature services. | High-integrity, permanent installations for critical, high-pressure/temperature, or hazardous service. | Small-bore piping (typically ≤ 2″), high-pressure systems where compact size and reliability are key. |

Key Advantage | Easy installation & removal. Allows for precise alignment and use of gaskets for a seal. Facilitates future system modifications. | Provides the strongest, most reliable leak-proof joint. Smooth bore for excellent flow. No gaskets to fail. | Stronger than threaded connections, easier to align for welding than butt-welds. Good for tight spaces. |

Key Consideration | Gasket stress and selection is critical for seal integrity. Requires more space. Potential for flange face damage. | Permanent installation. Requires highly skilled welding, post-weld heat treatment (PWHT), and Non-Destructive Testing (NDT) like radiography for code compliance. | Socket crevice can be problematic for corrosive or erosive services. Requires proper gap allowance to prevent weld cracking. |

Pressure/Temperature | Excellent for a wide range, limited by gasket and bolting materials. | Best for the most extreme pressure/temperature limits. | Excellent for high pressure, typical in small-bore instrument and utility lines. |

Installation Focus | Bolt tightening sequence and torque to ensure even gasket stress and prevent leaks. | Weld procedure qualification, welder skill, and NDT access for inspection are paramount. | Proper pipe insertion depth and gap allowance to manage thermal expansion. |

How to Choose: Key Selection Criteria to be used by Engineers

When specifying valve end connections, move beyond habit and apply these critical filters to your application:

- Process Criticality & Service Conditions: For lethal, toxic, or extremely high-energy services (e.g., main steam lines, hydrocarbon pipelines), the superior integrity of a butt-weldoften justifies the higher installation cost. For general process or utility services where isolation is needed, flanged connections offer practical flexibility.

- Inspection and Maintenance Philosophy: Does your plant run for years between turnarounds, or do you need to routinely isolate and remove equipment? Flanged valves are essential for any application where regular maintenance, calibration (for control valves), or replacement is anticipated. Permanent weld-end valves minimize potential leak points but require system shutdown for any work.

- Piping Specifications and Code Compliance: Your system’s piping class dictates materials and connection types. Ensure your valve selection meets the same code compliance standards (ASME B16.34, B31.1/B31.3). The need for NDT access on welds is a major factor in choosing and locating weld-end valves.

- Space Constraints and Weight: In compact skids or modules, the extended length and space needed for flange bolt clearance can be prohibitive. Socket-weldor butt-weld valves provide a much more compact solution. Also, consider that large-diameter, high-pressure flanged valves are very heavy and require robust support.

Partnering with IPC for the Right Connection

At IPC, we provide more than just valves, we deliver engineered solutions. Our comprehensive range of Gate, Globe, Check and Ball Valves is available in all standard end connections, manufactured in our 25,000+ sq. ft. facility. Our technical team, drawing from experience across 12+ sectors, can guide you through this selection process.

We understand that specifying a valve means considering its entire lifecycle within your specific system whether it’s for a hydrocarbon application boiler & steam application, a chemicals production process or an effluent treatment plant. By choosing IPC, you gain a partner committed to ensuring your valve’s connection is as reliable as the valve itself.

The choice between flanged, butt-weld, and socket-weld end connections is a fundamental engineering decision with lasting consequences. By systematically evaluating your system’s pressure, temperature, maintenance