Cost is not the first point where your thinking about implementing valve automation should start!

The first thought when adopting new technology should be safety.

Automated valves are connected to smart systems. Smart systems need two key assurances to work smoothly -uninterrupted power and protection from cyber-attacks.

If automated valves miss the timely directions from smart systems, it could mean a disaster! Anything from fugitive emissions to serious disruptions in media flow could endanger the safety of humans and machines alike.

This is where failsafe valve actuators come to your rescue!

A failsafe valve actuator is an actuator that returns the valve to a pre-determined ‘safe’ position upon loss of power. The high reliability of such actuators makes them a popular choice in hazardous industrial environments.

What type of actuator to consider?

Spring-return (pneumatic) actuators: In these actuators, a spring is compressed using air pressure to move the valve into the desired position. When the power holding the spring is cut off, the energy in the spring is released, reversing the valve’s motion.

Electric actuators with battery backup: Here, the actuator relies on batteries as an alternative source of power to operate the valve in the event of a power loss.

Should the valve fail close or fail open?

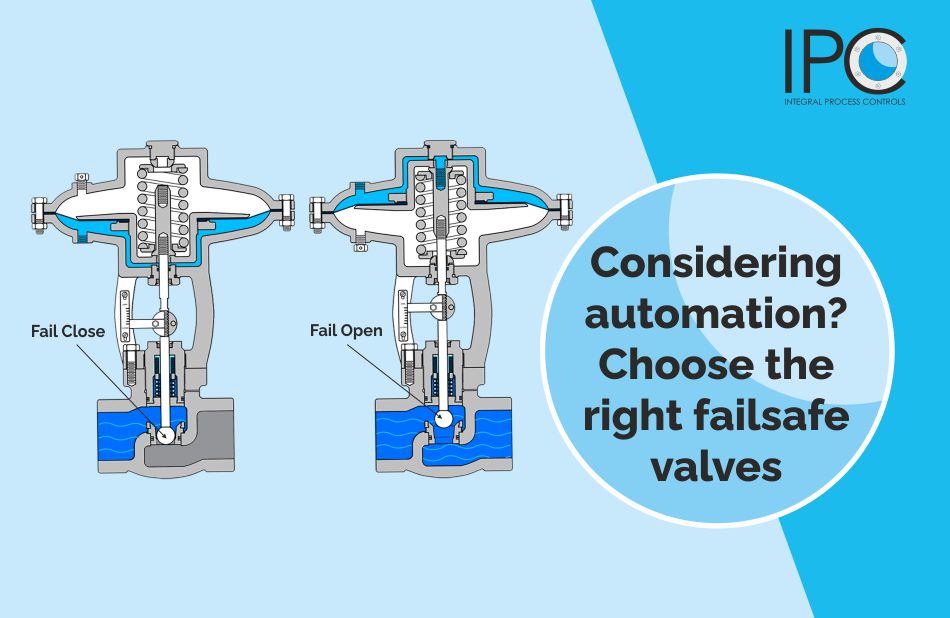

The valves could be set in Fail Open (FO), Fail Close (FC), or Stay-put. Depending on this, they will either open, close, or stay in the same position following a power loss.

The choice of the failsafe position depends on the nature of the application. If the valve is being used in a back pressure application such as holding pressure on a separator, it is the best set to ‘fail open. If the valve is being used in a pressure-reducing application, such as for suction control on a gas compressor, it should be set to ‘fail close’. To put it forth a different perspective, we can also decide the fail position considering the normal position of the valve in which it remains most of the time.

Conclusion

There exist non-failsafe valves that typically remain locked in the last position after the failure of power. They are generally used in high-thrust applications. However, failsafe valves provide more reliability and better safety to your operations. Additionally, electric actuators can handle more rounds of failure-induced emergent positioning than spring-operated valves. Certain types of valves can be reversed from Fail Open to Fail Close and visa-versa as per your changing needs. At the end of the day, the nature of the application, and the requirements of your operation decide everything!

Explore other factors to consider in valve automation on our blog here