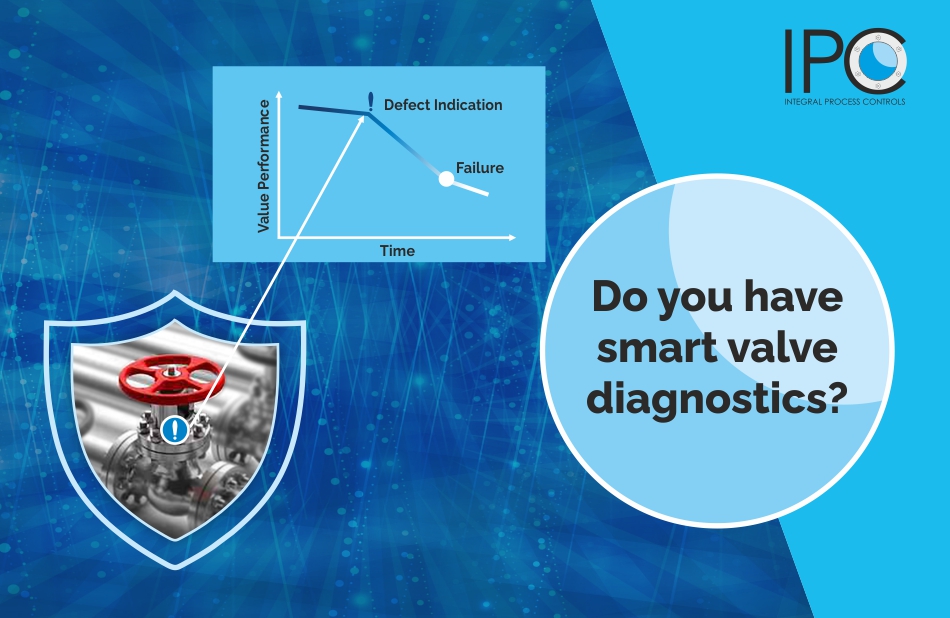

The critical performance parameters of valves are now being monitored by intelligent software. When the valve deviates from set parameters, a warning is sent to your desk. The software program has already identified the fault, and the technician now only needs to follow the recommendations made to correct it!

Smart valve diagnostics enables evaluation and analysis of valve performance in real-time, providing maintenance recommendations specific to the problem.

A smart controller or positioner device is fitted to the valve to monitor its performance in real-time. The relevant operating and diagnostic parameters are displayed in real-time on your screen. A host of algorithms analyses the data to instantly detect faults and even recommends action with step-by-step instructions.

How smart diagnostics help

Today, process companies need to ensure maximum process uptime with fewer resources including less labour and lower costs. The average time between turnarounds is being extended to 3-5 years, or even more. This extended runtime means there is not much of an opportunity to take valves out of service for diagnostics. Automation is often implemented with automatic on/off valves, but these valves are not capable of detecting and discriminating faults. If these critical valves fail, it could lead the entire process to shut down. Smart valve diagnostics have been developed specifically for in-service valve maintenance, allowing more uptime.

- Smart diagnostics enables predictive, in-service maintenance allowing more uptime.

- A prior warning of fault allows proactive planning to avoid an unplanned shutdown.

- Data collected by the smart controllers can be used to predict future problems before they disrupt the process.

- Real-time analysis and fault identification allow technicians to devise customized solutions for valves.

Conclusion

As process automation itself increases, turnaround times will rapidly decrease, making downtime unacceptable. Additionally, the man-hours available for valve maintenance will also be drastically reduced. Smart valve diagnostics thus matters more than ever in the near future. Judging by the current developments, smart valve diagnostics will also develop further to provide specific indications of what faults need to be fixed, list out required parts, drawings and the details of persons suited to perform valve repairs.