When a tourist hits the beach, he will immediately jump into the sea for a great swim. But first, he would have to consider certain factors. The weather, the tide of the sea, the condition of the beach, and his own capability.

Could he manage enough strokes to keep his body floating in the water?

Will he have enough force to swim through the waves?

These actions require significantly strong muscles. If the muscles fail to provide energy for the right strokes and force to swim, the consequences could be life-threatening.

In the case of valves, the actuators are the muscles that help the valve ‘swim’ against the force of the flowing media and operate smoothly. If they fail, the consequences could be dangerous.

Here are 3 key factors to consider when selecting a valve actuator

Nature of application

It is best to take a dive into the sea at high tide. Also, check the force of the water currents and the contours of the seafloor. This gives the tourists an idea of the sea’s ‘nature’ before swimming.

Similarly, The load of the media and the desired speed of actuator response are two critical factors impacting actuator choice. For instance, Pneumatic actuators respond quickly to open or close valves, but hydraulic actuators are better suited to handle more load. Electric actuators are fairly easy to install and use, but are more vulnerable to fire and explosions than other actuators. They cannot be used in sensitive areas.

Force

“Do I have enough force to swim through the waves?” is what a matured swimmer will ask themselves before hitting the beach. In the case of valves, the fore is the amount of force required to move the valve. This could be a rotary force for rotary actuators or a linear push-pull force for linear actuators.

The force refers to the force needed to open or close the valve.

The force required to operate a valve is in turn influenced by a number of factors such as size and design of the valve, stem packing friction, differential pressure, and valve torque among others.

This implies the amount of force required to move the valve from the open position to the closed one. The force required would be a linear push-and-pull force in a sliding stem valve, whereas multi-turn or part-turn valves require a rotary force. A number of factors such as – minimum and maximum supply pressure, actuator type, fail mode, and valve torque are required to determine the amount of force required.

Apart from this, the force of the media flow also needs to be considered. The velocity and force of the media can affect the selection of other parts of your linear actuator such as the nuts, ball screws, and motors. The impact force of the media will aid in choosing the right size and capacity of the motor for the actuator.

Ease of use

From hitting the beach to operating valves, tasks are enjoyable and rewarding if they can be done without much hassle. Valves should be easy to install and operate, and actuators play a key role here. For instance, pneumatic actuators are the easiest to install and operate while hydraulic ones are the most difficult to operate and need significant maintenance.

The good old-fashioned hand-wheels also deserve consideration in this area. The power and posture of human operators need to be considered when designing handwheels for valves. This entire thought is covered in human factor engineering in valves. Human factor engineering is the science of considering human capabilities and applying the knowledge to the design and selection of equipment, as well as processes and systems at work.

Explore the details of human factor engineering

Conclusion

What’s common in operating a valve and swimming in the sea is that it looks easy and smooth, but could be disastrous if the key component isn’t well suited for the task: The muscles, which in the case of the valve are its actuators.

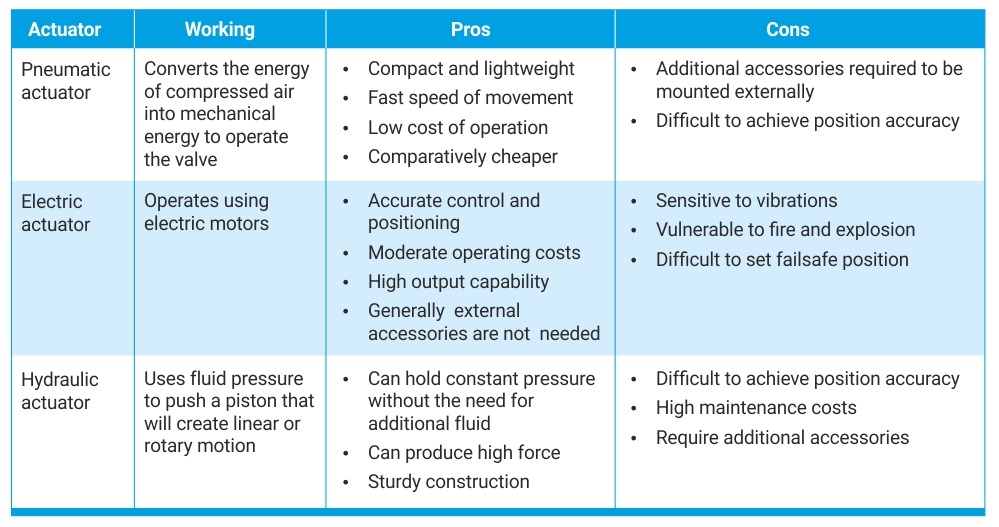

The key to choosing a good actuator is to look beyond the price and emphasize safety and efficiency in operations. Hence, the users must consult with the valve manufacturer on the choice of the actuators. The table given below offers a quick glance at the pros and cons of different actuators. Ensure you choose the one that best suits your needs.

Explore other factors to consider in valve automation on our blog here