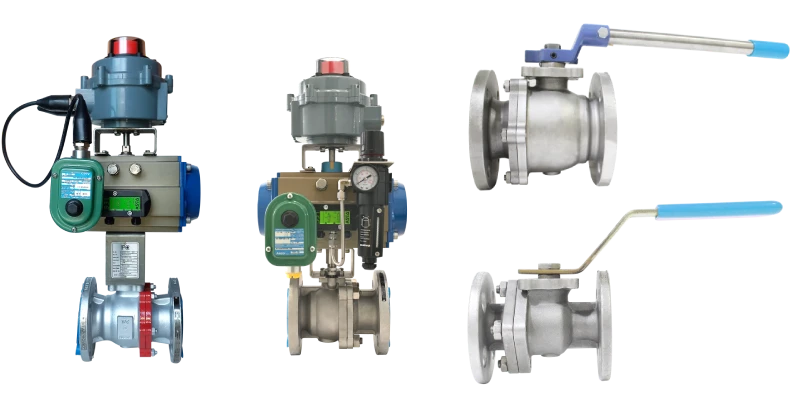

Floating Ball Valve

Reliable and Efficient Floating Ball Valves for Industrial Applications

IPC’s floating ball valve is a versatile solution known for its reliable performance and efficient flow control. With a floating ball design, it allows the ball to move freely, ensuring tight sealing and reduced torque requirements. Ideal for various industries such as oil and gas, chemical and water treatment, the floating ball valve offers excellent shut-off capabilities, low-pressure drop and ease of maintenance. Its wide range of material options, sizes and pressure ratings make it suitable for diverse applications, providing reliable and cost-effective valve solutions.

Benefits

Blowout-proof stem

Soft and metal-seated

Variety of actuation options

Antistatic feature

Cavity Pressure Relief mechanism

Specifications

General design & mfg ISO 17292 / ASME B 16.34

Valve face to face dimensions ASME B 16.10

Top Flange drilling ISO 5211

Valve inspection and testing API 598 / BS EN 12266 Part 1 Flange

Drilling ASME B16.5 / Others upon request

Features

Fire-safe to ISO 10497 and API 607

High Sphericity Mirror-finished solid stainless ball

Actuator-mounting range conforms to ISO 5211

SIL3 Safety Integrity Level for Automated Valves

FET Test ISO 15848 Emissions

Certifications

Downloads

Frequently Asked Questions

The key difference is in the ball mounting. In a trunnion-mounted ball valve, the ball is fixed on a shaft for very high-pressure applications. In a floating ball valve, the ball is free to move, which allows line pressure to assist in sealing. This makes floating designs an excellent, cost-effective choice for a wide range of high-pressure duties.

Our valves are designed for durability and consistent performance.

Key benefits include:

- Bubble-tight sealing for reliable shut-off.

- Robust construction with a sturdy design for easy maintenance.

- Wide material compatibility (carbon steel, stainless steel, alloy steel) to handle various media.

- Easy quarter-turn operation with low torque.

Thanks to their robust sealing, they are ideal for oil and gas, petrochemical, power generation, and other process industries. They excel in applications involving oil, gas, steam, water, and corrosive fluids where a dependable shut-off is critical.

We use high-performance materials to ensure longevity. Common seat materials include Reinforced PTFE (RPTFE) and Nylon for excellent chemical resistance and low friction. For more demanding services, we offer options like PEEK and metal-seated designs.

Absolutely. The simple quarter-turn operation makes floating ball valves perfectly suited for automation. We can fit them with pneumatic or electric actuators for remote control and integration into your process automation systems.