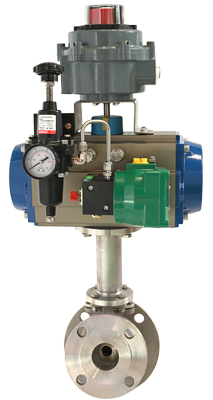

Flush Bottom Ball Valves

High-performance flush bottom valves, engineered for optimal tank draining efficiency. Designed with precision, these valves offer reliable sealing to prevent leaks during the draining process. Their bottom-mounted design ensures complete emptying of tanks, eliminating residual liquids and debris. Ideal for industries like chemical processing, pharmaceuticals, and food and beverage, our flush bottom valves are built to withstand harsh environments. Experience hassle-free maintenance with quick access for inspection and repairs. Elevate your tank draining capabilities with our exceptional flush bottom valves.

Benefits

Anti-blow out stem design

Compact Ball type design

Cavity filled design ensures zero fluid entrapment

No stagnation of fluid above the ball

Actuator mounting pad adhering to ISO 5211

Specifications

General design & mfg ASME B 16.34

Face to face dimensions Manufacturers Std.

Inspection and testing BS EN 12266 Part 1 / API 598

Flange drilling ASME B 16.5

Size range DN 40 to DN 200

Pressure rating Class 150

Features

Quarter turn design ensures fast operation

Jacketted design options for temperature requirements of specific processes

Complete absence of cavities inside the valve ensures that there is no problem associated with deposition and solidification of fluid

Available in various materials as per customers' specific requirements

Sturdy, reliable and low maintenance construction

Certifications

Downloads

Frequently Asked Questions

What is a Flush Bottom Ball Valve, and what does it do?

It is an ultimate drain valve for tanks, reactors or vessels. It’s specifically designed to be mounted directly on the bottom nozzle of a tank. When open, it provides a full, unobstructed flow path. When closed, its ball sits flush with the tank’s interior wall, ensuring that virtually no product is left behind in the valve body it allows you to empty the tank completely.

Why is the "flush" design so important?

The flush design solves two big problems. First, it prevents product residue buildup in a valve cavity, which is critical for maintaining purity between batches in food, pharma, or chemical processes. Second, it eliminates a dead leg where fluids could stagnate, making cleaning, sterilization, and process changeovers much faster and more effective.

What industries benefit most from these valves?

Any industry that needs to fully drain a vessel or maintain strict hygiene uses them. They are common in chemical processing, pharmaceuticals, food & beverage, paints & coatings and resin handling essentially anywhere you’re dealing with viscous liquids, corrosive materials, or sensitive products where complete evacuation and cleanliness are a must.

What are the main design features for safety and performance?

IPC’s flush bottom valves are built for reliability. They often feature a robust uni-body, which makes maintenance easier without removing the valve from the tank. A key focus is on achieving a leak-proof, zero-cavity seal to prevent any seepage or contamination. Materials are chosen for corrosion resistance against the specific process media.

What should I consider when selecting a flush bottom valve?

Key factors are the tank connection size and standard, the properties of the fluid (is it viscous, abrasive, corrosive?), the operating pressure and temperature, and any specific needs like aseptic standards or fire-safe requirements. Sharing these details ensures you get the right valve.

Why choose IPC for such a critical tank valve?

As a leading manufacturer, we understand that a valve on the bottom of a tank is a critical safety and reliability point. Our flush bottom ball valves are engineered for maximum sealing integrity and durability in demanding service. We focus on providing a safe, reliable solution that ensures complete drainage and protects your process.