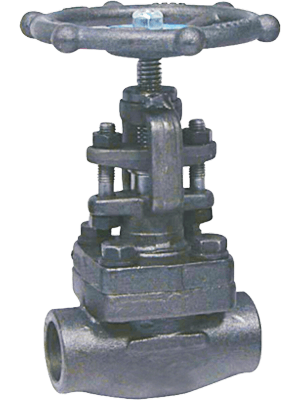

Forged Steel Globe Valves

High Performance & Superior flow control

IPC’s complete range forged steel globe valves – setting new standards in performance and reliability. Designed for chemical, petrochemical, pharmaceutical, steel, food, power and water/steam industries. Experience seamless automation with optional electrical actuator operation. Choose from socket weld, butt weld or screwed end connections for easy integration. Trust in their durability, precision and adaptability to elevate your processes. Join satisfied customers who rely on IPC’s globe valves for exceptional results. Make the smart choice for your business

Benefits

Flow control accuracy and durability

Robust construction and reliable sealing

Available in a variety of sizes, pressure ratings, and end connections

Suitable for a wide range of applications across industries

Automatically adjusts the slight misalignments caused by pipeline deflections & thermal deformation

Specifications

General design & MFG API 602/ISO 15761/ASME B 16.34

Pressure Temperature rating ASME B 16.34

Face to face dimensions Manufacturer's standard

Inspection and testing API 598 / BS 12266-1

End connections ASME B16.11

Size range DN 15 to DN 50

Seat leakage API 598

Pressure class 800 / 1500 / 2500 / 4500

Features

Outside screw & yoke (OS & Y) construction (for gate & globe valve)

Stronger and corrosion resistant bolting ensures long life and better sealing

Various trim materials are available (in accordance with API 602)

Gland packings can be replaced without removing the valve from the pipeline

Actuated valves can be provided with pneumatic / electrical actuator

In pressure classes #1500 and above bonnets come in welded design

Certifications

Valves Approvals

Downloads

Frequently Asked Questions

What is a forged steel globe valve?

A forged steel globe valve is a flow-control valve made from forged steel instead of cast material. Forging improves strength, density, and reliability, especially in high-pressure and high-temperature services.

Why are forged steel globe valves preferred over cast valves?

Forged valves have a tighter grain structure, fewer internal defects, and better pressure resistance. That makes them more dependable in critical applications where failure isn’t an option.

What are forged steel globe valves mainly used for?

They’re used for throttling and flow regulation in oil & gas, power plants, petrochemical units, refineries, and steam systems where precise control is required.

Are forged steel globe valves suitable for high pressure and temperature?

Yes. This is where they perform best. Forged construction allows the valve to handle extreme pressure and temperature conditions with long-term stability.

What bonnet types are available in IPC forged steel globe valves?

IPC offers different bonnet designs such as bolted bonnet, welded bonnet, and pressure seal bonnet, depending on pressure class and service conditions.

What materials are used in IPC forged steel globe valves?

These valves are typically manufactured using carbon steel, alloy steel, and stainless steel, with trim options selected based on media and operating conditions.