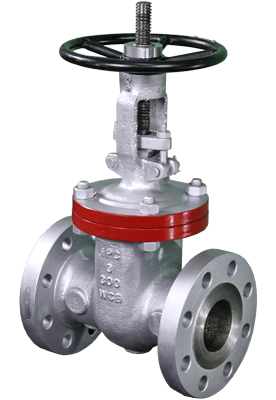

Gate Valve Bolted Bonnet

Gate Valve Manufacturers in India

IPC manufactures the full range of Gate Valve, which are ideal for bi-directional, low friction flow and shut-off as per international standards. Due to the flow characteristics of the wedge to seat design, Gate Valves are always operated in the full close or full open position.

IPC manufactures wide range of sizes in gate valve right from 2” to 24” (DN- 50 to DN -600) and pressure rating ranges from ASME class 150 through 4500. Higher pressure rating and bigger sizes can also be provided.

Benefits

Thoughtful design delivers accurate performance

Automatically adjusts the slight misalignments caused by pipeline deflections & thermal deformation

Gate valve Manufacturing with advanced processes for best results and longevity

Superior strength due to Single piece forged Stem

Minimum torque due to flexible wedge/Split wedge construction

Specifications

Pressure rating ASME class 150 through 4500

Sizes - 1/2" to 24" (DN-15 to DN-600)

MFG standards - API 600 / BS 1414 / ASME B16.34 / MSS SP-144

Flange details - std as per ASME B16.5 Others as per BS, AWWA, EN, DIN, etc.

End to end dimensions - as per ASME B16.10

Testing standards - API 598 / BS EN 12266-part 1

Butt-weld end details - as per ASME B16.2

Features

Flanges: Standard as per B16.5 and others as per BS, AWWA, EN, DIN Etc

Raised face with serrated finish (125-250 AARH) – Other options available

Seat rings are seal welded with body to eliminate leakage and accidental loosening of the seat ring

One piece bonnet design

Flexible wedge/Split wedge with balanced design to minimize vibrations due to flow that minimizes stress concentration

Highly finished seat face with lapping

Rising stem – trapezoidal threads and burnished finish

Pillar yoke construction for easy access to bonnet & packing rings for maintenance

One piece cast flexible wedge

Certifications

Valves Approvals

Downloads

Frequently Asked Questions

Our trust comes from dedicated process expertise and scale. We combine proven design standards (like API 600 and ASME B16.34) with in-house manufacturing control. Operating from a large facility with over 120 specialists, we ensure every valve from raw material to final testing meets high standards of reliability for our customers.

We provide a comprehensive range, including the common Bolted Bonnet Gate Valve, along with Pressure Seal Bonnet designs for high-pressure systems. Our valves come in various sizes, materials (like Cast Carbon Steel, Stainless Steel, Alloy Steel), and trim options to handle different pressures, temperatures, and media types.

This is a classic, robust design where the valve body (which holds the pressure) and the bonnet (the “lid” that provides access to internal parts) are sealed together by a ring of strong studs and nuts. This creates a secure, reliable seal that makes it perfect for a wide range of industrial pressures and temperatures. It’s known for its durability and ease of maintenance.

This is often the best choice for general industrial service across oil & gas, power, chemical, and water applications. It’s especially suitable for systems with moderate to high pressures where a leak-proof seal is critical, and where you might need to access the valve internals for inspection or maintenance over its long service life.