A drawing can promise performance. A test stand proves it. Hydrostatic (shell) testing and seat-leak testing are where a valves are proven to that they ready for installation and operations

Seat-leak testing. What gets tested and why

- Shell (hydro) test: checks the pressure boundary of body/bonnet for strength and porosity. The valve is partially open, filled with clean water, and pressurised (per API 598 / design standard such as BS-EN ISO 12266). Hold time and stabilization ensure readings are true. Acceptance is simple: no visible leakage through the pressure boundary.

- Backseat test (where applicable): confirms the stem backseat integrity when fully open.

- Seat-leak test: proves shut-off tightness of the seating surfaces. The valve is closed and pressure is applied from each side in turn (bi-directional where required). Acceptance follows API 598 leakage criteria soft-seated typically zero visible leakage, metal-seated has tight allowable limits by size/class.

- Pressures, mediums, times done as per predefined standards.

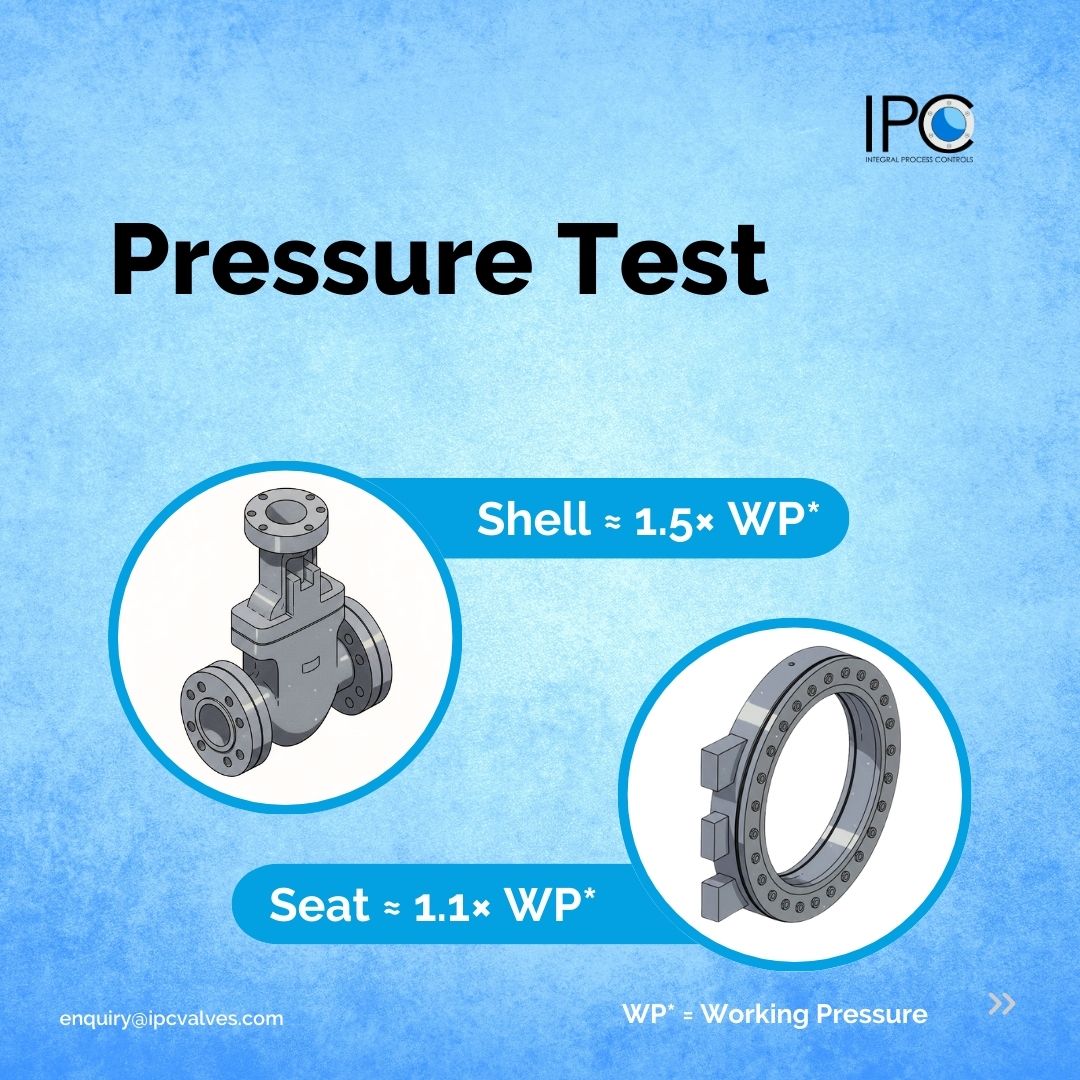

- Test pressures and hold times are defined by the standards and the pressure class. (Commonly, shell ≈ 1.5×WP rated cold working pressure; seat ≈ 1.1×WP as specified in API 598.)

- Medium: clean water with corrosion inhibitor; temperature within the standard’s window.

- Stabilization: pressure settles before timing begins; gauges are calibrated and readable.

What procurement teams should see

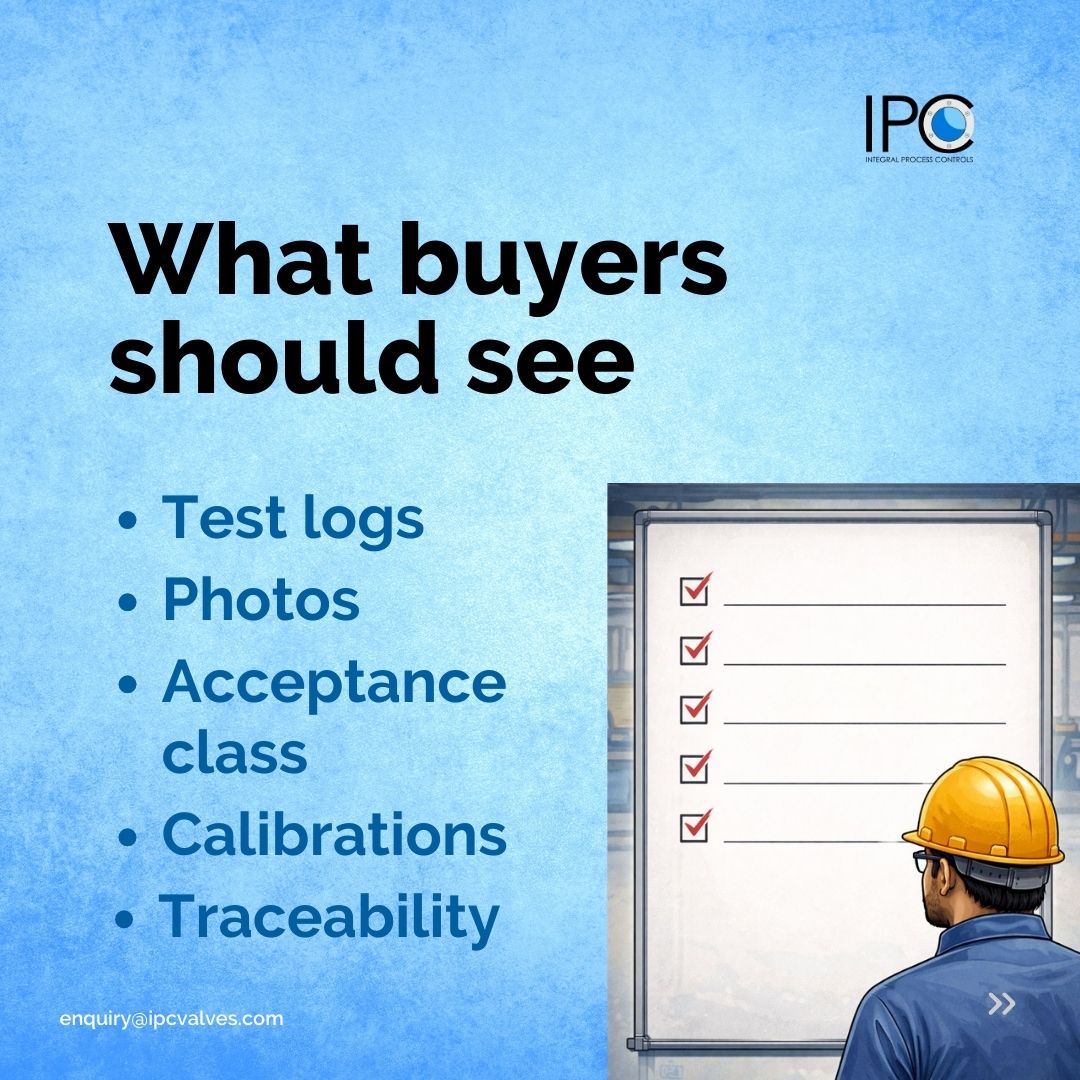

- Calibrations (gauges, recorders, relief devices) valid at test date.

- MTRs/MTCs, valve serial match, and traceable test records: shell, backseat (if applicable), and seat-leak results, with pressures/hold times, orientation, and acceptance class.

- Visual evidence where needed: photos or digital charts from the test stand.

The IPC Way

IPC runs every valve through a documented API 598 test plan. We log pressures and times digitally, mark acceptance against the correct class, and bundle everything into the MDR so your auditors and operators see the same truth we do. Tested, traceable and ready for duty.