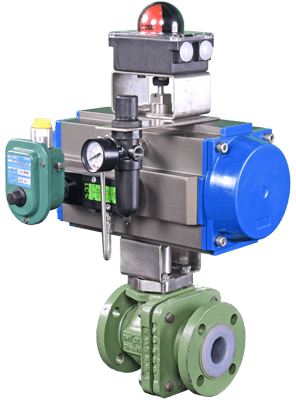

PFA Lined Ball Valves

Specialised Valves for Corrosive Materials

The ultimate choice for corrosive materials. Designed for demanding chemical applications, our PFA Lined Ball Valves deliver exceptional performance and durability. Trust in their reliability while handling highly corrosive or reactive substances. Widely used in chemical, minerals, fertilizers, pharma and more… our valves provide a trusted solution for diverse industries. Elevate your processes with our PFA Line ball valves, ensuring optimal performance and peace of mind in the face of challenging chemical environments.

Benefits

Bubble-tight shutoff

Low maintenance & low emission

Superior corrosion resistance

Long Lasting durability

Specifically designed for chemical applications

Specifications

Pressure Rating : Class 150 /PN 16

Sizes : 1/2" to 12"

Mfg Standards : ISO 17292 / ASME B 16.34

Testing Standards : API 598 / BS EN 12266-1

End Details : ASME B 16.5 / DIN PN 10 / JIS

Face To Face : ASME B 16.10

Features

Metal components in investment castings, ensuring intact and homogeneous lining

Even thickness of lining at intricate contours

Flange dimensions in DIN, ANSI and JIS standards

Options in ISO mounting pad design, enables mounting of actuators very easy

All lining materials for corrosive applications such as PFA, FEP, PVDF, ETFE, ECTFE and PPH

Standard body casting material is ASTM A 216 GR. WCB and upon requirement can also provide ASTM A 351 GR. CF8 or CF8 M / ASTM A 890 GR. 4A (CD3MN) / Super Duplex

Frequently Asked Questions

It’s a specialized ball valve designed with a superpower: a PFA (Perfluoroalkoxy) plastic lining on the inside. This lining acts as a highly resistant barrier between the corrosive fluids you need to control and the metal body of the valve itself, protecting it from damage.

PFA is a champion material when it comes to resisting chemicals. It offers exceptional durability and corrosion resistance against a vast range of aggressive acids, bases, and solvents. This means the valve lasts much longer and maintains a reliable seal in environments that would quickly degrade standard valves.

Any industry that handles reactive or highly corrosive substances can benefit. They are widely trusted in chemical processing, pharmaceutical manufacturing, fertilizer production, mineral processing, and other sectors where fluid purity and equipment integrity are critical.

The biggest benefit is peace of mind. You get a reliable valve that ensures optimal performance and safety in challenging chemical environments. This translates to reduced downtime, lower risk of leaks or failures, and long-term cost savings by protecting your process and equipment.

If your process involves highly corrosive, reactive, or high-purity fluids where contamination or metal degradation is a concern, then a PFA lined valve is likely an excellent choice. Our team can help confirm based on your specific chemical, temperature, and pressure conditions.