This doesn’t surprise us anymore

- Delivery in 30 mins

- Never going to your bank

- Buying almost everything online

- Paying for chai and vada-pav online

- Cellphone becoming the primary device to conduct business

- Meeting our friends and doing professional networking in the meta verse

- Online/Digital only schools, colleges and Universities

- IoT devices telling you what you need and when you should buy

- Intelligent washing machines that save water, roti makers that manage nutrien

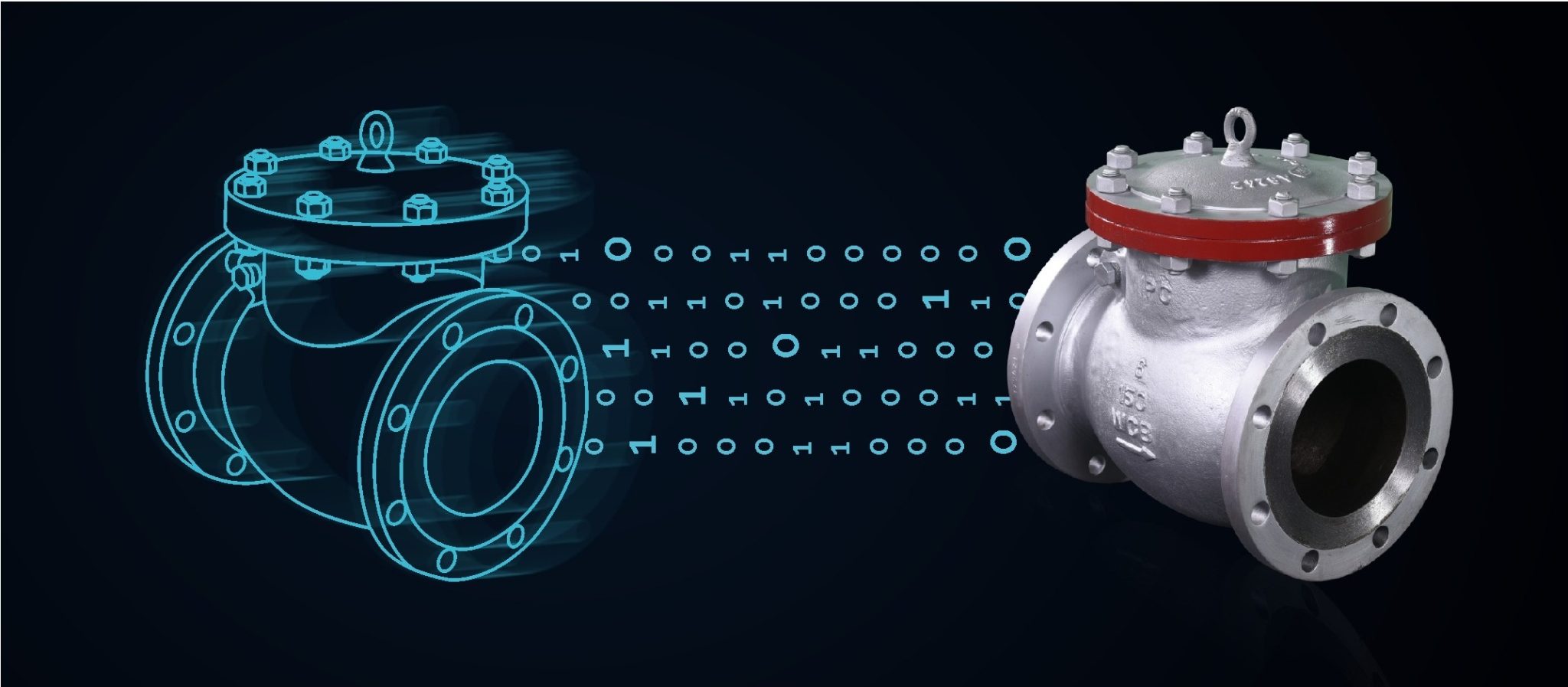

Valve Manufacturer what to expect in the future valve

?

As a valve manufacturer like IPC Valve, you can anticipate several significant trends and developments shaping the future of valve technology:

-

Advanced Valve Materials

Expect the use of more advanced materials for valve construction, including alloys and composites that offer better durability, corrosion resistance, and performance in extreme conditions. -

Smart Valves:

Industrial valves will increasingly incorporate smart technology, enabling remote monitoring, predictive maintenance, and automation. This will enhance efficiency, reduce downtime, and optimize operations. -

Valve IoT Integration:

The Industrial Internet of Things (IIoT) will play a significant role. Valves will be integrated into larger IIoT systems, allowing for real-time data collection and analysis to improve overall system performance. -

Energy Efficiency in valve:

Valve manufacturers will focus on developing energy-efficient valves to align with global sustainability goals. These valves will help industries reduce energy consumption and lower their carbon footprint. -

Customization in valves:

There will be a growing demand for customized valves designed to meet specific industrial requirements. Manufacturers will need to offer flexible solutions to accommodate diverse applications. -

3D Printing use in valves:

Additive manufacturing techniques like 3D printing will be used to create complex valve designs efficiently, reducing lead times and enabling rapid prototyping. -

Valve Safety and Compliance:

Valve manufacturers will need to stay updated with evolving safety regulations and industry standards to ensure that their products meet the required compliance criteria. -

Environmental Considerations:

Environmentally-friendly valves and materials will gain prominence as industries strive to minimize their impact on the environment. This may involve developing valves that are easier to recycle or use in closed-loop systems. -

Global Expansion:

As industries expand globally, valve manufacturers will need to establish a global presence to meet the increasing demand for industrial valves worldwide. -

Training and Expertise:

Manufacturers will invest in training programs and knowledge sharing to ensure that technicians and engineers are well-versed in the operation and maintenance of complex industrial valve systems. -

Supply Chain Optimization:

Companies may explore ways to optimize their supply chains, including localized production or distribution centers, to reduce lead times and ensure the availability of valves when needed. -

Cybersecurity in Valve:

With the increased connectivity of valves through IoT, cybersecurity will become a critical concern to protect against potential cyber threats.

At IPC Valves, we are already working on the things that will shape the future of customer expectations. For instance, we have reduced the lead time to procure valves significantly. We are developing smart help manuals that will aid easy and quick maintenance.

We have a high commitment to deliver world-class and futuristic product and services to you, always.

For any requirements in Gate, Globe, Check and Ball Valves, Motorised/Automated Valves, Pneumatic Actuator and Limit Switch Boxes, get in touch with us at evalve@ipcvalves.com