The global standard for actuator integration. How IPC’s designs support easy automation upgrades.

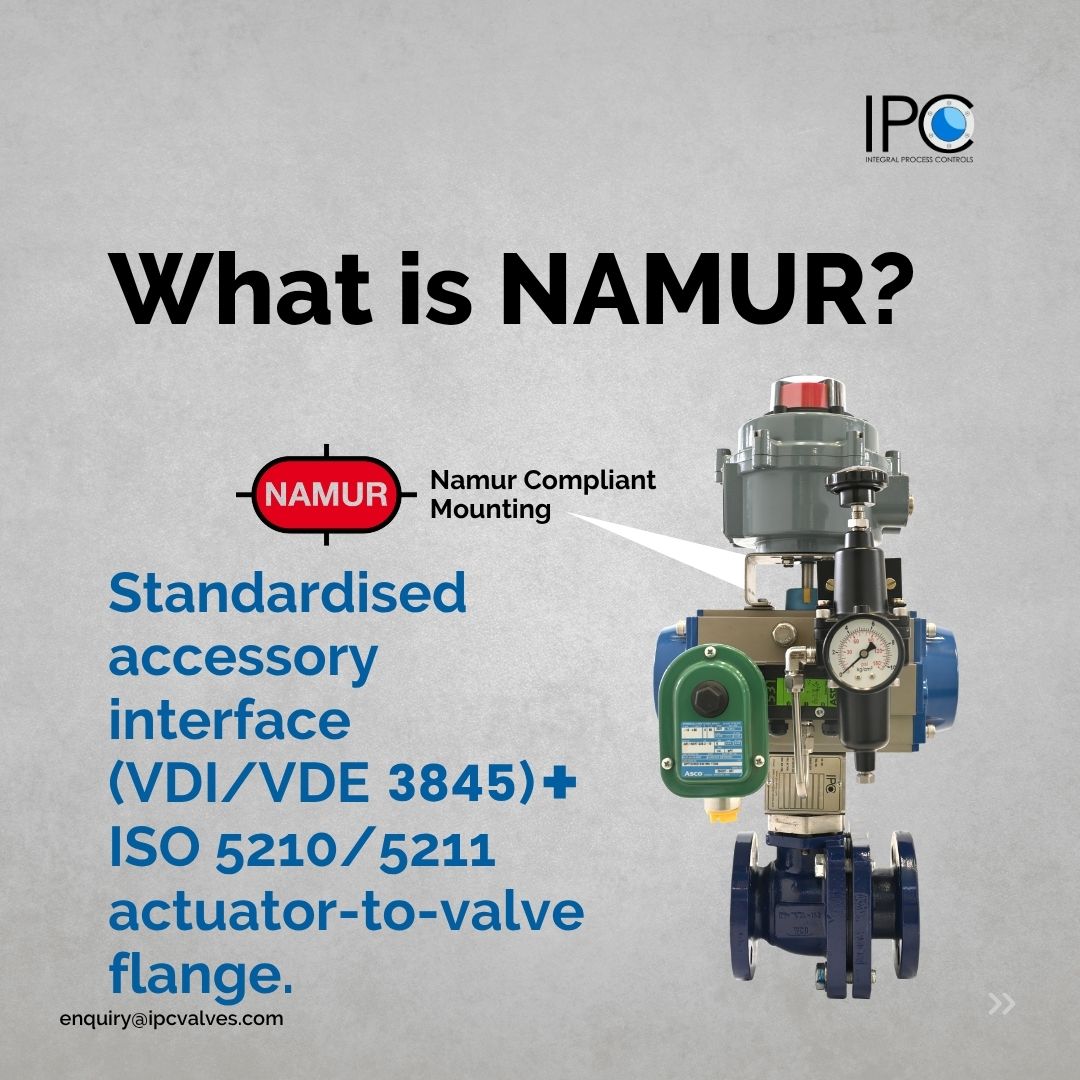

What “NAMUR mounting” means

“Trim” means the internal parts that actually control the flow and seal. Think disc/wedge/plug, seat rings, stem, back-seat, guides, and any hard-facing on these parts. These pieces see the most punishment pressure drops, velocity, temperature, and the process media itself so getting their material and surface right is the single biggest lever for long valve life.

Why trim selection / choice changes valve longevity

In valve automation, NAMUR mounting refers to using standardised hole patterns and interfaces so accessories (like solenoid valves, limit switches, and positioners) fit any compliant actuator without custom brackets or tubing.

In practice, you’ll meet two closely related standards on modern automated valves:

- VDI/VDE 3845 (often called “NAMUR interface”) defines the accessory mounting interface on quarter-turn actuators (the side/top patterns used to mount pilot/solenoid valves and accessories).

- ISO 5210 / 5211 – defines the actuator-to-valve drive interface (flange pattern and drive shaft/insert).

Together, they let you mix-and-match valves, actuators and accessories from different brands with plug-and-play ease.

Why NAMUR matters in actuator mounting

1. Interchangeability = less downtime

Need to swap a solenoid valve or positioner? NAMUR gives you a common bolt pattern and port alignment, so replacements bolt straight on no re-fabrication or re-piping.

2. Fewer parts, cleaner installs

Because the accessory can be mounted directly to the actuator, you eliminate add-on brackets and long tubing runs. That means fewer leak points, tighter response, and a neater, safer assembly.

3. Faster commissioning & upgrades

Standard patterns mean repeatable centerlines and heights. Technicians spend less time aligning and more time commissioning. Upgrading from a basic on/off to a smart positioner is simpler when the mounting footprints are predictable.

4. Consistent performance

Short pilot paths and solid mounting reduce hysteresis and lag. The result is crisper actuation, more stable control, and easier troubleshooting across your installed base.

5. Future-proofing

Plants change. NAMUR lets you adopt new accessory tech (low-power coils, smart feedback, digital positioners) without redesigning the hardware around the valve.

How IPC ensures 100% compliance (and easy life for your maintenance team)

- Correct interfaces by design

IPC actuated assemblies use ISO 5210 / 5211 flanges/drive inserts for the valve actuator connection and VDI/VDE 3845 (NAMUR) patterns for accessory mounts. Hole spacing, thread sizes, and shaft geometries are kept to spec no surprises in the field. - Precise tolerances & alignment

We control flatness, concentricity and parallelism on the mounting faces so accessories sit flush and stems turn true minimising side loads, wear, and calibration drift. - Ready ports, right where you expect them

Accessory air ports and gasket faces follow the standard locations, enabling direct mount solenoids (NAMUR pattern) with short, rigid connections that improve response and cut leak paths. - Materials & coatings for real plants

From corrosion-resistant fasteners to coated brackets (when needed), IPC builds for steam, hydrocarbons and outdoor duty so the standard stays usable for years.

NAMUR mounting turns automation into plug-and-play. By aligning with VDI/VDE 3845 for accessories and ISO 5210 / 5211 for actuator flanges, IPC gives you clean installations, easier upgrades, faster commissioning, and consistent performance across brands.

Planning an upgrade or a mixed-brand install? Ask IPC for a NAMUR-ready package tailored to your media, temperature and duty cycle.