In a modern plant, control systems confirm valve states electronically but, on the floor, decisions are often made in seconds. A clear, top-mounted visual indicator on a limit switch box (LSB) turns position into certainty at a glance, helping teams move faster, safer and with higher confidence.

What a good indicator delivers

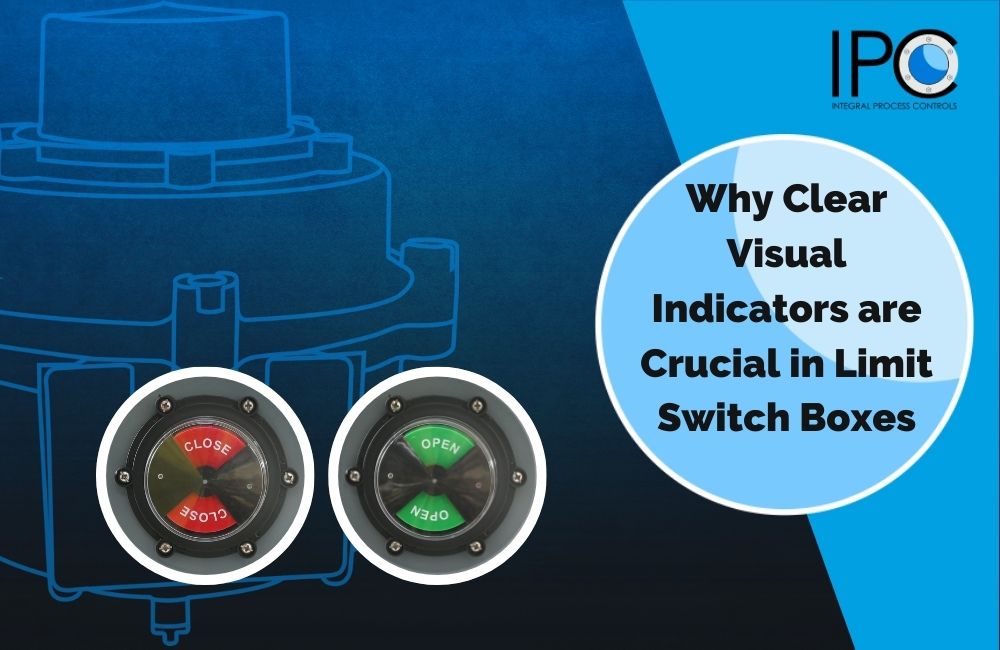

Instant legibility:

A 3D, top-viewable dome or pointer that reads Open/Close from aisles and platforms.

True-to-position:

Mechanical linkage to the actuator shaft so the display matches the valve, not just a signal.

Common language:

Green = Open, Red = Closed, consistent across lines and shifts.

Why on-site visuals still matter

Electronic feedback is vital, but field work happens in real time, in noise, heat and distance. A clear, top-mounted visual indicator gives local, human-readable truth bridging control-room data and what the valve is actually doing.

- Instant isolation checks (LOTO): During rounds, changeovers and permit-to-work, technicians confirm Open/Closed at the valve no radio, no delays.

- Faster diagnostics: If DCS says “open” but the indicator shows “closed,” you’ve narrowed the fault to linkage, cams, actuator jam, air loss or wiring cutting troubleshooting time.

- Safer interventions: Before approaching a hot/chemical line, teams visually confirm state on site an extra layer of confidence beyond screens.

- Operational resilience: If networks lag, I/O fails or power/communications drop, the mechanical indicator still shows true position useful for cybersecurity-aware plants too.

Built for the real world:

IPC limit switch boxes use IP67-rated enclosures that resist water, dust and chemicals.

Correct design of a limit switch box position indicator should take four fundamental points into consideration:

- High mechanical strength to protect against falling objects

- High resistance to worst weather conditions

- Visibility from all sides

- Easy and fast adjustment

Our stainless-steel shafts with robust linkages that hold accuracy under vibration and thermal cycling available in Flameproof and Weatherproof variants to match area of classification.

Glass Cover / Outer Dome

The outer dome cover is typically made of glass, though polycarbonate versions are also used. A glass cover is recommended when polycarbonate cannot withstand chemical or solvent exposure, or under prolonged extreme temperature conditions.

Design choices that reduce ambiguity (IPC approach):

Indicators are top-mounted and 3D so they’re readable from aisles and platforms, displays are mechanically linked to the actuator shaft so what you see is the true position. Limit switch boxes use materials and seals selected for long-lasting clarity, with a focus on mechanical accuracy rather than decorative styling.

Quick selection checklist

- Readability at distance and typical approach angle

- Mechanical linkage (no free-spinning caps)

- IP/NEMA rating

- Clear color semantics (Open/Closed)

- Area classification and mounting fit

In plant performance and safety, clarity is capability. Choose limit switch boxes whose indicators remain readable and truthful for years that’s how you keep operations smooth and decisions confident.