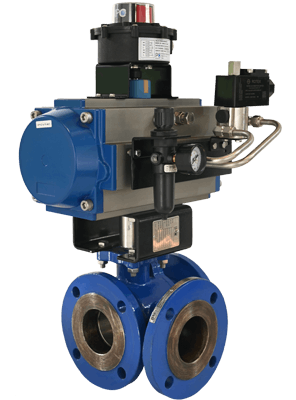

3 Way Floating Ball Valves

Get exceptional flow control with 3 way ball valve

Engineered with precision, these valves offer exceptional versatility and performance. The L-Port and T-Port configurations allow for seamless switching between flow directions, providing optimal control and flexibility. Perfect for applications requiring mixing, blending or diverting fluids, these valves find extensive use in industries such as chemical processing, oil and gas and water treatment. Experience superior flow control and unleash the potential of your processes with IPC’s 3 WAY FLOATING BALL VALVE (L-PORT & T-PORT).

Benefits

Blow-Out Proof Stem

Low emission packing

Ideal for applications that require mixing, blending, or diverting fluids

Efficient and consistent flow

Specifications

General design & mfg BS EN ISO 17292 / ASME B 16.34

Valve face to face dimensions MANUFACTURING STANDARD

Flange drilling ASME B16.5

Top flange drilling ISO 5211

Valve inspection and testing API 598 / ISO 5208

Features

ISO 5211 Mounting Pad Allows for mounting of actuator.

Maintenance free live loaded double sealing stem packing ensures high cycles life and positive sealing.

Full Bore body, avoids clogging and ensures smooth flow when handling slurries and solid.

Body cavity fillers available.

Seating is available for all 3 ports.

Certifications

Downloads

Frequently Asked Questions

Think of it as a traffic director for your pipes. Unlike a standard on/off valve with two ports, a 3-way valve has three. This allows you to do more than just stop flow you can use it to switch flow between different lines, mix two streams into one, or divert one stream into two directions, all with a simple quarter-turn.

Their ability to manage multiple flow paths makes them ideal for applications requiring mixing, blending, or diverting. You’ll find them in chemical processing, oil and gas systems, water treatment plants, HVAC, and industrial automation where processes need to be flexible and efficient.

You get exceptional flow control and versatility from a single, compact unit. They simplify your piping by replacing multiple two-way valves, provide reliable sealing with the floating ball design, and their quarter-turn operation allows for quick and easy changes to your process flow.

Beyond choosing the right port type (L or T), key factors are the fluid type, operating pressure and temperature, required port size, and material compatibility. Sharing your specific application with our team ensures you get the perfect valve for the job.

It all comes down to the shape of the passage drilled through the ball:

- An L-Port (where the bore makes a 90-degree “L” shape) is perfect for diverting flow. It connects one inlet to one of two outlets, switching between them. You typically cannot have all three ports open at once.

- A T-Port (where the bore looks like a “T”) offers more flexibility. It can be used to divert, mix, or even allow flow straight through all three ports, depending on the handle position.