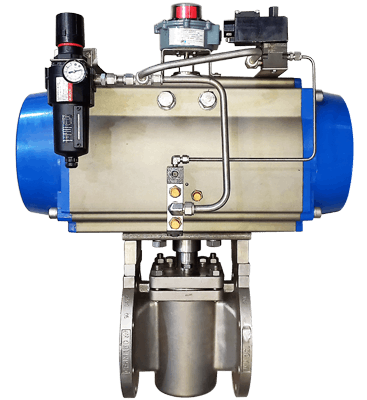

Sleeved Plug Valves

Leak proof and reliable sealing with sleeved plug valve

Benefits

Suitable for a wide range of industries, including oil and gas, chemical processing

Offers quick and effortless flow control

Excellent resistance to corrosion, wear and harsh operating conditions

Minimize the risk of leaks or accidental releases

Specifications

Pressure Rating Class 150 / 300

Sizes 1/2" to 12"

Mfg Standards As per manufacturer

Testing Standards API 598

End Details ASME B 16.5

Face To Face ASME B 16.10

Features

Excellent sealing mechanism

Lower maintenance cost and longer service life

Easy to automate and operate quarter turn mechanism

Better control over emissions

Certifications

Downloads

Frequently Asked Questions

Sleeved plug valves are the go-to choice for slurry-type media—thick, abrasive mixtures of liquids and solids common in mining, wastewater treatment, pulp and paper, and chemical processing. Their robust design and reliable sealing also make them suitable for a wide range of other industrial applications where leak-proof performance is critical.

You get a combination of durability, safety, and low maintenance. The compressible sleeve provides a leak-proof seal that lasts, reducing downtime and environmental risks. Their versatile and robust construction ensures long-term reliability, even in demanding conditions, giving you peace of mind for your operations.

The most important factors are the type of media (especially if it’s abrasive or a slurry), operating pressure and temperature, and required valve size. Sharing these details with our team allows us to recommend the perfect valve from our range. You can explore more on our dedicated Sleeved Plug Valves page or contact our experts at Enquiry@ipcvalves.com.