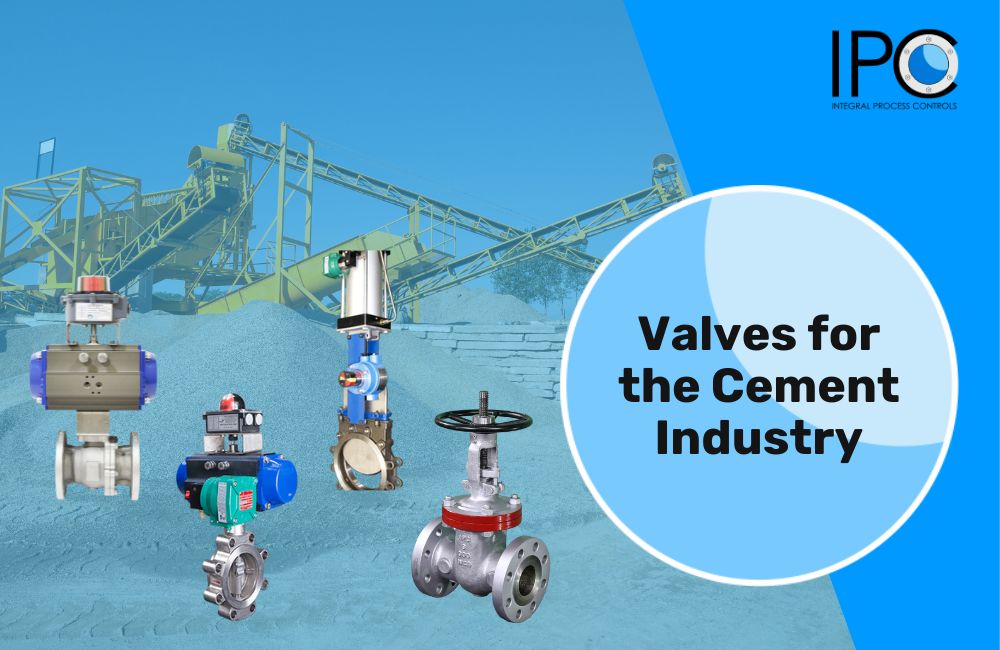

Cement manufacturing is a highly intricate process that involves handling abrasive materials, converting powders to slurry, and managing complex workflows. In such an environment, the choice of valves plays a crucial role in ensuring operational efficiency and durability. IPC Valves, with its 20+ years of expertise in manufacturing specialised valves, offers a complete range of valves to suit the unique demands of cement manufacturers.

Here are four valves that act as the backbone of Cement manufacturing plants

Floating Ball Valves: Control Air and Water flows

In the cement industry, managing airflows and water is essential for various processes. IPC Valves’ Floating Ball Valves are designed to provide optimal performance. These valves offer quick shut-offs, contributing to the efficient regulation of airflows and water in cement manufacturing. The durability of IPC’s Floating Ball Valves is unmatched, making them a reliable choice for the demanding conditions of the cement industry.

Butterfly Valves: Regulate Bulk Materials Flow

Regulating the flow of bulk materials, particularly in process raw materials, is a critical aspect of cement manufacturing. IPC Valves’ Butterfly Valves offer a cost-effective solution with low pressure drops, enabling seamless control over material flow. These valves are designed to withstand the demanding nature of bulk materials, providing durability and longevity in service.

Gate Valves: handle steams for CCP

Steam plays a crucial role in various processes within a cement plant. Right from preheating and drying to hydration and cleaning, steam is utilized in different ways to facilitate these processes. The robust design of Gate Valves from IPC makes them an ideal choice for handling and managing steam.

Knife Edge Gate Valves: Handle In-Process Slurry Material

Handling in-process slurry material requires valves that can withstand abrasion and provide reliable bi-directional sealing. IPC Valves’ Knife Edge Gate Valves are specifically engineered for this purpose. These valves excel in managing abrasive materials commonly found in slurry, offering the durability and efficiency needed for uninterrupted operations.

Choose IPC Valves for Cement Industry Needs

IPC Valves stands out as the preferred choice for the cement industry due to its commitment to delivering high-quality solutions tailored to the unique challenges of cement manufacturing. Whether it’s controlling airflows, regulating bulk material flow, managing essential materials, or handling slurry, IPC Valves provides a comprehensive range of valves that excel in performance and longevity.